Introduction

The world of manufacturing is undergoing a rapid transformation, driven by advancements in technology, changes in consumer preferences, and a growing focus on sustainability. As we navigate the evolving landscape of industry, manufacturers must stay ahead of the curve.

Manufacturing Industry Trends

In this article, we will explore ten key trends that are set to dominate the manufacturing sector in the coming years.

1. Industry 4.0 and Smart Manufacturing

Industry 4.0 represents the integration of digital technologies into the manufacturing process. Smart factories are equipped with sensors, IoT devices, and AI, enabling real-time data analysis and decision-making. This trend will enhance efficiency, reduce downtime, and optimize production processes.

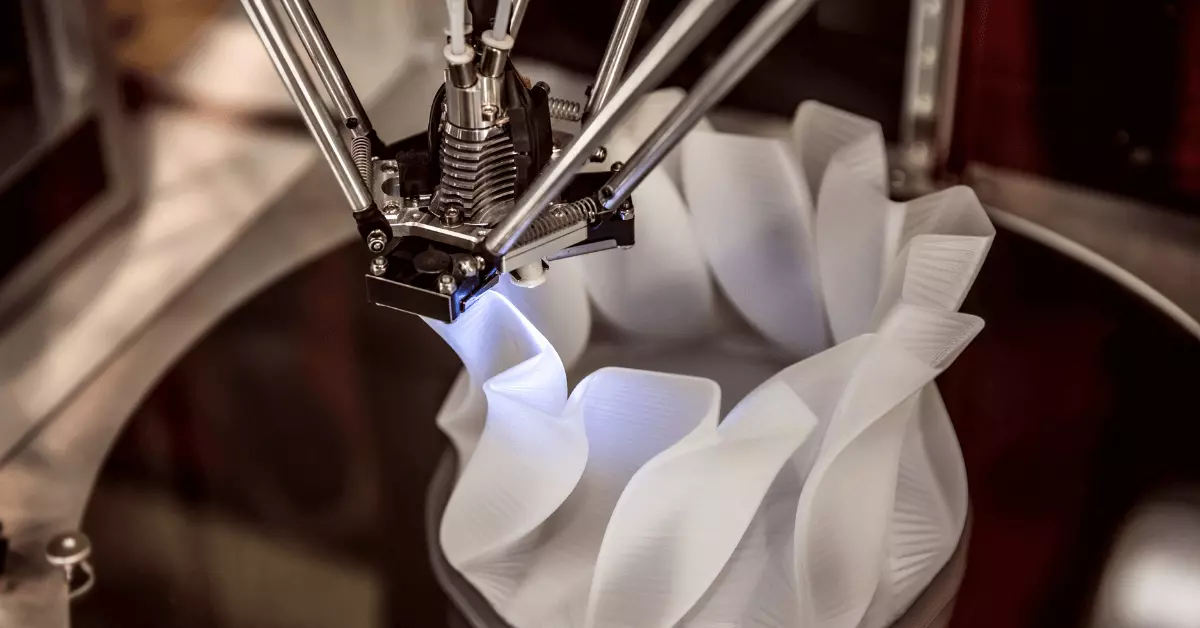

2. Additive Manufacturing (3D Printing)

3D Printing is revolutionizing manufacturing by enabling the creation of complex, customized products with greater precision and speed. From aerospace components to medical implants, additive manufacturing is expanding its reach across various industries.

Related report: Global 3D Printing Materials Market

3. Supply Chain Resilience

The disruptions caused by the COVID-19 pandemic highlighted the importance of resilient supply chains. Manufacturers are diversifying suppliers, investing in inventory management tools, and embracing digital solutions to ensure continuity.

4. Sustainability and Green Manufacturing

Eco-conscious consumers are driving the adoption of sustainable manufacturing practices. Companies are reducing waste, implementing circular economy principles, and embracing renewable energy sources to reduce their environmental footprint.

Also read: Sustainable Chemical Manufacturing Trends

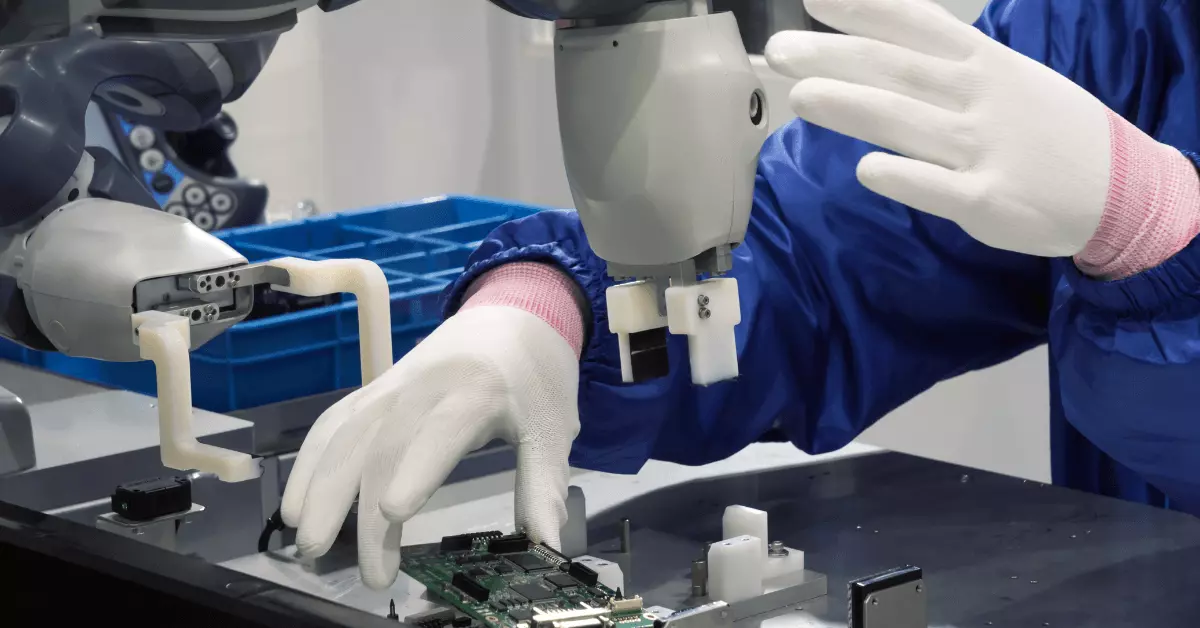

5. Robotics and Automation

Automation continues to streamline manufacturing operations, from assembly lines to logistics. Collaborative robots (cobots) are becoming more prevalent, enhancing human-machine collaboration and increasing productivity.

Also read: How Artificial Neural Networks Optimize Manufacturing Process

6. Artificial Intelligence (AI) and Machine Learning

AI and machine learning algorithms are being used to optimize production processes, predict maintenance needs, and enhance quality control. These technologies are indispensable for achieving greater efficiency and competitiveness.

7. Blockchain Technology

Blockchain technology is being increasingly used within the manufacturing industry. Industry 4.0 spans across a whole network of machines, parts, equipment, and value chain participants. Therefore, as factories around the world become increasingly interconnected, the influence of blockchain is becoming more prevalent. Importantly, blockchain technology will bring greater transparency and trust to the manufacturing sector.

Blockchain-powered solutions in the manufacturing sector can seamlessly aggregate all of the information to deliver significant value for manufacturing companies and help unlock the full potential of other advanced technologies, such as IoT, 3D printing, and augmented reality.

Related report: Blockchain in Healthcare Market

8. Reskilling the Workforce

The workforce of the future will require new skills to operate and maintain advanced manufacturing technologies. Training and upskilling programs are essential to ensure that employees can adapt to changing roles in the industry.

9. Advanced Materials and Nanotechnology

Breakthroughs in materials science are opening doors to stronger, lighter, and more durable materials. Nanotechnology is enabling the development of innovative products with unique properties, revolutionizing industries such as electronics and healthcare.

10. Augmented Reality (AR) and Virtual Reality (VR)

AR and VR are transforming manufacturing training, maintenance, and design processes. These technologies are improving worker skills, reducing errors, and enhancing product visualization.

11. Cybersecurity in Manufacturing

As manufacturing becomes increasingly digital, the need for robust cybersecurity measures grows. Protecting sensitive data and critical infrastructure from cyber threats is paramount for maintaining trust and continuity.

12. Industrial Internet of Things (IIoT):

Internet of things in industries, where interconnected devices are used in industrial settings and manufacturing establishments to collect data that can then be used to enhance the manufacturing process. Examples of these interconnected IIoT devices include sensors, devices, machinery/equipment, and the software that powers them. In 2021, the global Industrial Internet of Things (IIoT) market is estimated at nearly US$ 200 billion. Some of the best IIoT providers include ABB, Cisco, Huawei, Intel, among others.

Potential risks or challenges associated with these trends

While these trends have brought about numerous benefits, they also present a set of potential risks and challenges that manufacturers must navigate to remain competitive and sustainable.

We will explore some of the key challenges associated with the evolving trends in manufacturing.

Supply Chain Disruptions

One of the most pressing challenges in modern manufacturing is the vulnerability of global supply chains. The COVID-19 pandemic highlighted the risks associated with overreliance on offshore suppliers and the lack of redundancy in the supply chain.

Manufacturers may face disruptions due to natural disasters, geopolitical conflicts, trade disputes, or unexpected events like the pandemic. To mitigate these risks, manufacturers are now exploring strategies such as nearshoring, reshoring, and investing in digital supply chain technologies.

Technological Adoption and Cybersecurity

The adoption of advanced technologies like IoT (Internet of Things), robotics, and automation has enhanced efficiency and productivity in manufacturing. However, it has also opened up new avenues for cyberattacks. Manufacturers are increasingly vulnerable to cyber threats that can disrupt operations, compromise sensitive data, or even pose safety risks in connected production systems. Ensuring robust cybersecurity measures and investing in employee training are crucial to safeguard against these risks.

Skilled Workforce Shortages

The digitization of manufacturing processes demands a workforce with advanced skills in technology, data analysis, and automation. However, there is a shortage of skilled workers in many regions, leading to challenges in recruiting and retaining talent. Manufacturers are addressing this issue through partnerships with educational institutions, upskilling programs, and creating more appealing work environments to attract the younger generation.

Environmental Regulations and Sustainability

Sustainability is a growing concern for manufacturers as environmental regulations become stricter and consumers demand eco-friendly products. Compliance with environmental standards can be costly, and failure to do so can lead to fines and reputational damage. Manufacturers must invest in sustainable practices, optimize resource usage, and develop eco-friendly products to remain competitive and meet regulatory requirements.

Complexity in Data Management

The rise of Industry 4.0 and the Industrial Internet of Things (IIoT) has generated massive amounts of data from manufacturing processes. Effectively managing and leveraging this data for improved decision-making is a challenge. Manufacturers need robust data analytics tools and skilled data professionals to make sense of the data deluge and extract valuable insights.

Trade Uncertainties

Global trade dynamics are constantly evolving, and manufacturers can be affected by tariffs, trade disputes, and changes in international trade agreements. Such uncertainties can disrupt supply chains, increase costs, and impact market access. Manufacturers should closely monitor trade policies, diversify their markets, and consider alternative sourcing strategies to mitigate these risks.

The Road Ahead

The manufacturing industry is poised for significant changes in the coming years, driven by technology, sustainability, and evolving consumer demands. Embracing these trends will be crucial for manufacturers to remain competitive, efficient, and environmentally responsible. By staying informed and adapting to these shifts, companies can position themselves for success in the dynamic world of manufacturing.

To know more about the current market scenario for the Manufacturing Industry, request a sample.

Divyanshu Sharma

Co-founder and Director at RationalStat

Divyanshu is an experienced market research consultant. He helps growth-driven organizations and entrepreneurs understand market entry prospects, industry assessment, and grow their revenue strategically.